Encountering moisture in your electrical panel is not just an inconvenience—it’s a potential safety hazard. The presence of moisture can lead to corrosion, short circuits, and even fire, making it crucial to understand why it happens and how to prevent it. This article delves into the often-overlooked issue of moisture intrusion in electrical panels and offers practical solutions to safeguard your home or business.

- Moisture can enter your electrical panel due to factors like poor sealing or temperature changes, posing a risk to your safety.

- To diagnose moisture issues effectively, employ tools such as thermal imaging and moisture meters.

- Simple preventative measures like proper insulation and ventilation can keep your electrical panel dry and operational.

- Professional evaluation and maintenance by certified electricians can prevent hazards and ensure long-term safety.

By understanding and addressing the causes of moisture in your electrical panel, you can enhance the safety and efficiency of your electrical system. This guide equips you with the knowledge and techniques required for proper diagnosis and prevention, encouraging you to adopt proactive strategies for better maintenance.

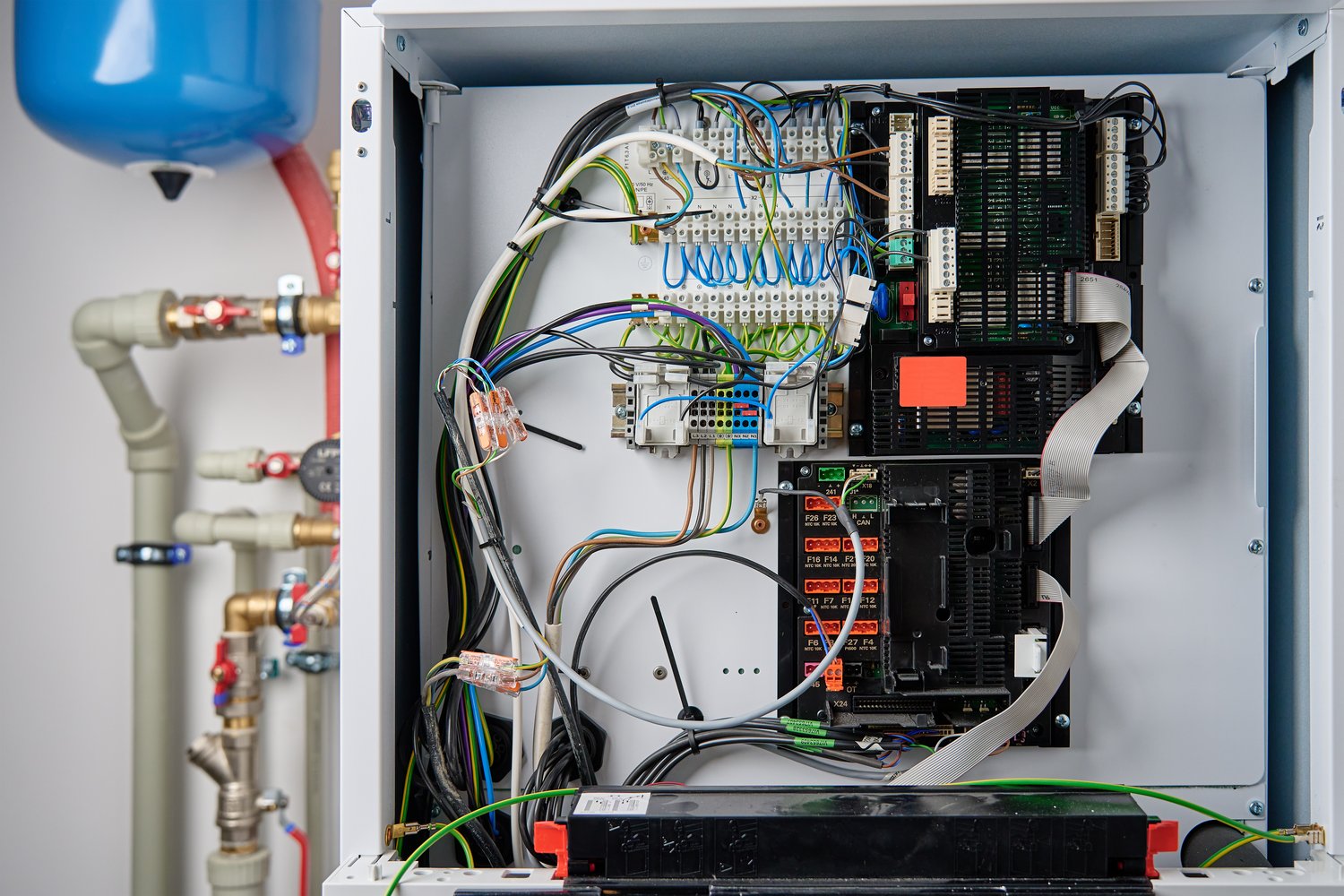

Diagnosing Moisture Issues: Steps and Tools

Addressing moisture in your electrical panel begins with a thorough diagnosis. Detecting moisture early is vital for preventing electrical hazards and promoting safe operations.

One effective method is to use thermal imaging, a non-invasive technique that can detect variations in temperature, indicating potential moisture presence. A sudden temperature drop often signifies moisture lurking behind the surface.

Another approach is employing moisture meters. These devices are highly efficient in measuring moisture levels within the panel’s environment. Available in both pin and pinless models, moisture meters deliver precise readings to help you pinpoint trouble spots.

Start diagnosing by visually inspecting your electrical panel. Look for signs of rust, corrosion, or water staining, which could suggest excessive moisture.

The tools and steps mentioned are crucial components when diagnosing and addressing water-related issues in your electrical panel.

Preventative Measures for Keeping Electrical Panels Dry

Preventing moisture from entering your electrical panel safeguards against potential disasters. Establish reliable preventative measures to maintain panel integrity and performance.

Ensure proper insulation around your panel to prevent moisture infiltration through gaps or cracks. High-quality sealant can be applied to fill any spaces prone to leaking.

Ventilation also plays a critical role in regulating temperature and humidity. Ensure that your electrical space has adequate airflow to evaporate any moisture build-up swiftly.

Regular maintenance checks are essential. Schedule periodic inspections with a certified electrician to examine the panel and surrounding areas for potential water intrusion.

Utilize a dehumidifier in areas prone to high humidity, keeping the environment dry and free from excess moisture.

These preventative strategies are key in ensuring your electrical panel remains dry, enhancing both safety and efficiency.

Understanding Why Moisture Affects Electrical Panels: Complete Diagnosis & Prevention Guide

Moisture in electrical panels is not just a minor inconvenience; it can severely compromise their safety and efficiency. Recognizing why moisture is detrimental to the functionality of electrical systems is crucial.

Moisture can cause corrosion of electrical components, leading to potential short circuits and even fires. This not only endangers the safety of your home or business but also significantly reduces the lifespan of the equipment.

Moreover, when moisture infiltrates an electrical panel, it can disrupt the flow of electricity, causing tripping of circuit breakers or even complete power outages. This can hinder operations in commercial settings or compromise comfort and safety at home.

Understanding the sources of moisture and how it impacts your electrical system forms the foundation for accurate diagnosis and effective prevention strategies. Keeping your electrical panel dry is critical for optimal performance and safety, making it essential to address moisture issues promptly and thoroughly.

Common Causes of Moisture Intrusion

Identifying how moisture enters an electrical panel is the first step in troubleshooting and preventing further damage. There are several common causes of moisture intrusion:

Poor sealing of the electrical panel is a major contributor. Gaps or cracks in the panel’s housing can allow external moisture to seep inside.

Temperature fluctuations play a significant role. When warm, moist air comes into contact with cooler surfaces, condensation can occur within the panel.

Water leaks, whether from plumbing problems or roof defects, can lead to moisture entering your electrical system. This is especially true if the electrical panel is located in damp areas like basements or garages.

Understanding these sources is vital to take corrective actions. By identifying the root causes, you can implement preventive measures to protect your electrical panel from moisture-related issues.

The Role of Professional Evaluation and Maintenance

Ensuring the optimal performance and safety of your electrical panel requires regular evaluation and maintenance by a certified electrician. Professionals possess the expertise and equipment necessary to accurately assess potential issues related to moisture and other risks in your electrical system.

Regular evaluations help identify signs of moisture intrusion early, preventing costly repairs and enhancing the longevity of the panel components. An experienced electrician can use advanced tools like moisture meters and thermal cameras to pinpoint problem areas that may not be visible to the untrained eye.

During maintenance, professionals also check for any worn-out or damaged components that might contribute to moisture problems. They can suggest the installation of proper sealants or recommend ventilation improvements to effectively reduce humidity levels around the panel.

By scheduling periodic maintenance, you ensure that any potential hazards are proactively addressed, reducing the risk of electric shocks or short circuits. This not only improves electrical safety but also ensures compliance with local electrical standards and regulations.

Furthermore, leveraging a professional’s knowledge in modern technologies such as smart energy management systems can provide additional safeguards against moisture-related issues. Their advice on upgrading systems can lead to improved energy efficiency and reliability, benefiting both residential and commercial properties.

Ultimately, professional evaluations and maintenance are crucial investments in the long-term safety and efficiency of your electrical system.

FAQ Section: Moisture in Electrical Panels

What are common indications of moisture in an electrical panel?

Answer: Signs include rust, corrosion, and unusual odors emanating from the panel.

How can moisture affect the performance of my electrical panel?

Answer: Moisture can lead to short circuits, electrical arcing, and potential fire hazards.

What tools are essential for diagnosing moisture issues?

Answer: Essential tools include thermal imaging cameras and moisture meters.

Why should I consider professional help for moisture problems?

Answer: Professionals ensure proper diagnosis and maintenance, ensuring safety compliance.

Are there specific maintenance tips to prevent moisture build-up?

Answer: Yes, regular maintenance, proper insulation, and ensuring good ventilation are vital.

Can temperature fluctuations lead to moisture in the panel?

Answer: Yes, condensation can occur when warm air meets a cold surface, causing moisture build-up.

Is sealing electrical panels a good prevention strategy?

Answer: Ensuring proper sealing can reduce water ingress and help keep the panel dry.