Understanding the power of pneumatic tools

Pneumatic tools are essential for any professional workshop. These devices harness compressed air to perform various tasks efficiently. They offer significant advantages over traditional hand tools and electric alternatives. Pneumatic tools provide consistent power output, reducing user fatigue during prolonged use. Their lightweight design allows for easy maneuverability in tight spaces. Most pneumatic tools require minimal maintenance, ensuring long-term reliability. They operate at cooler temperatures compared to electric tools, making them ideal for continuous use. [PHRASE] (onninen.pl/en/products/Tools-and-OHS/Pneumatic-tools) come in various types, each designed for specific applications.

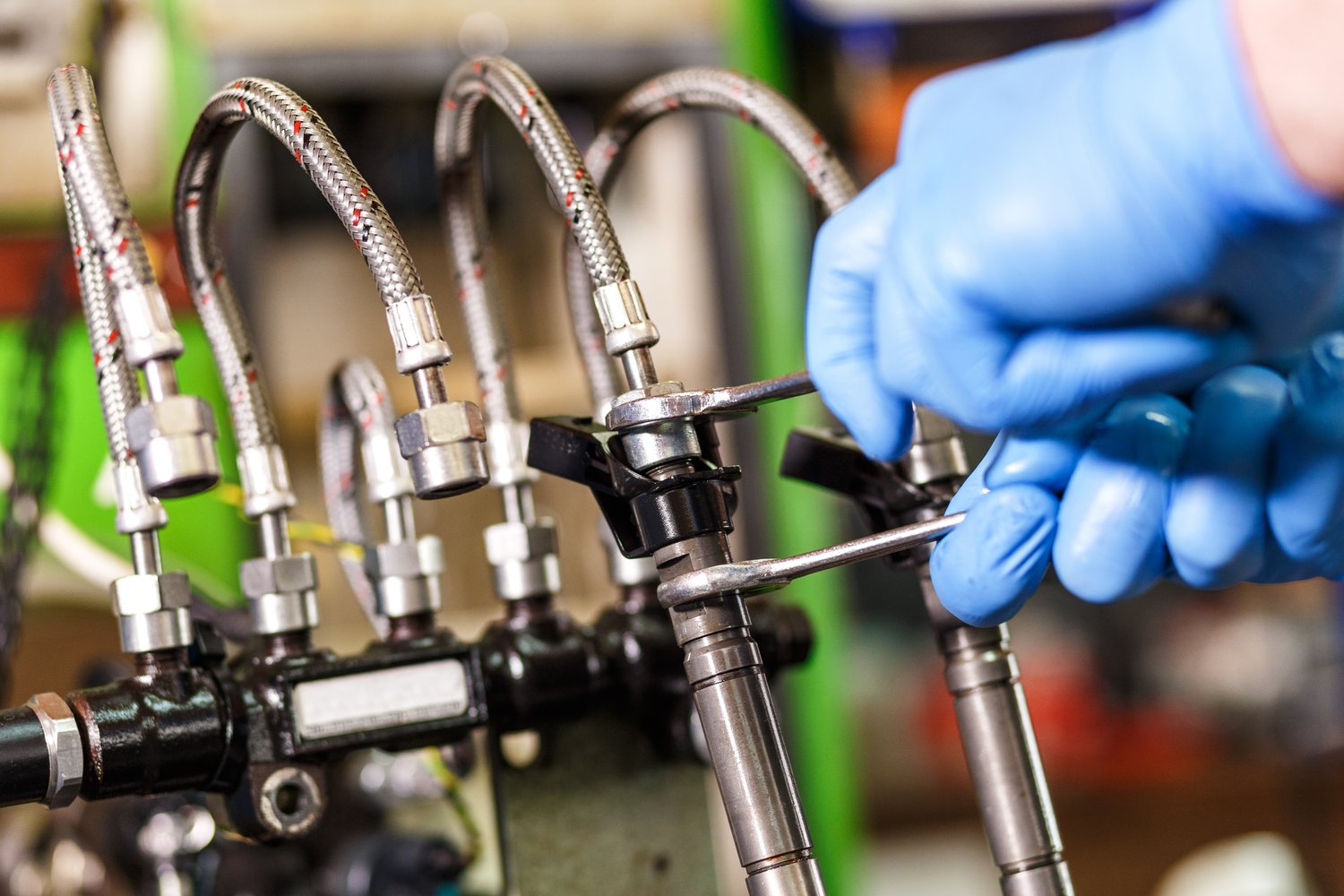

The versatility of pneumatic tools is unmatched. They can be used for drilling, cutting, grinding, and fastening. Many industries rely on these tools for their daily operations. Construction sites often utilize pneumatic jackhammers and nail guns. Automotive workshops depend on air-powered impact wrenches and spray guns. Woodworking shops benefit from pneumatic sanders and routers. The food industry uses air-driven packaging machines. Pneumatic tools offer precise control, allowing for accurate and repeatable results. They are particularly useful in assembly line production. Some pneumatic tools can operate in environments where electric tools might pose safety risks.

Proper maintenance is crucial for pneumatic tool performance. Regular cleaning prevents dust and debris buildup. Lubrication ensures smooth operation of moving parts. Checking air hoses for leaks helps maintain optimal pressure. Storing tools in a dry environment prevents internal corrosion. Following manufacturer guidelines for each tool is essential. Some pneumatic tools require specific air pressure ranges. Others may need particular types of lubricants. Proper training for operators enhances safety and efficiency. Keeping spare parts on hand minimizes downtime during repairs. Regular inspections can identify potential issues before they become serious problems.

Safety considerations are paramount when using pneumatic tools. Always wear appropriate personal protective equipment. This includes safety glasses, gloves, and hearing protection. Ensure proper ventilation in the work area to disperse air exhaust. Never use compressed air to clean clothing or skin. Disconnect tools from the air supply when not in use. Secure loose clothing and tie back long hair to prevent entanglement. Follow proper procedures for changing accessories or making adjustments. Be aware of the tool’s kickback potential during operation. Keep work areas clean and free of trip hazards. Regularly inspect air hoses for signs of wear or damage.

Exploring nailers and fittings for precise fastening

Nailers are among the most popular pneumatic tools. They significantly speed up fastening tasks in construction and woodworking. Framing nailers are designed for heavy-duty applications like house framing. Finish nailers are ideal for trim work and cabinetry. Brad nailers handle delicate moldings and small wood pieces. Roofing nailers streamline the process of installing shingles. [PHRASE] (onninen.pl/en/products/Tools-and-OHS/Pneumatic-tools/Nailers-and-fittings) come in various sizes to accommodate different nail lengths.

Choosing the right nailer depends on the specific job requirements. Consider the type of material you’ll be fastening. Think about the size and gauge of nails needed for the task. Evaluate the frequency and duration of use to select an appropriate model. Some nailers offer adjustable depth settings for precise nail placement. Others feature sequential or bump firing modes for different applications. Cordless nailers provide mobility but may sacrifice power for convenience. Magazine capacity is another factor to consider for efficiency. Some nailers can accommodate both strips and coils of nails. Ergonomic designs reduce user fatigue during extended use.

Proper maintenance ensures optimal nailer performance. Clean the magazine regularly to prevent jams. Lubricate moving parts according to manufacturer recommendations. Check for air leaks in the tool and hose connections. Adjust the exhaust direction to keep debris away from your work area. Keep spare O-rings and driver blades on hand for quick repairs. Store nailers in a dry place to prevent rust and corrosion. Inspect the safety mechanism before each use to ensure proper function. Use the correct air pressure specified for your nailer model. Clean the air inlet filter periodically to maintain airflow. Consider using a inline oiler for automatic lubrication during operation.

Safety is crucial when operating pneumatic nailers. Always wear safety glasses to protect against flying debris. Keep fingers away from the nail discharge area during operation. Disconnect the air supply when clearing jams or making adjustments. Never point the nailer at yourself or others, even if it seems unloaded. Be aware of your surroundings and potential ricochet hazards. Use the correct nail type and length for your specific application. Avoid using nailers on unstable surfaces or ladders. Inspect workpieces for knots or other irregularities that might deflect nails. Follow proper procedures for loading and unloading nails. Train all users on safe operating practices before allowing tool use.

Enhancing productivity with other air tools

Beyond nailers, a wide range of other air tools exists. Air ratchets and impact wrenches expedite automotive work. Pneumatic sanders provide smooth finishes in woodworking projects. Air hammers are indispensable for demolition and metalworking tasks. Spray guns offer precise control for painting and finishing. [PHRASE] (onninen.pl/en/products/Tools-and-OHS/Pneumatic-tools/Other-air-tools) include grinders, drills, and chisels. Each tool is designed to optimize specific tasks in various industries.

Selecting the right air tool depends on your specific needs. Consider the frequency and intensity of use required. Evaluate the available air pressure and volume from your compressor. Think about the ergonomics and weight for prolonged use comfort. Some air tools offer variable speed controls for versatility. Others may have specialized attachments for different applications. Noise levels can be a factor in certain work environments. Energy efficiency is important for reducing operational costs. Durability and repairability should be considered for long-term value. Some tools may require specific air preparation equipment like filters or lubricators.

Proper maintenance extends the life of air tools. Regular cleaning prevents buildup of dust and debris. Lubrication ensures smooth operation of internal components. Checking for air leaks helps maintain optimal performance. Storing tools in a dry environment prevents corrosion. Following manufacturer guidelines for each tool is crucial. Some air tools may require specific types of oil or grease. Others might need periodic replacement of wear parts. Keeping spare seals and O-rings on hand minimizes downtime. Regular inspections can catch potential issues early. Proper training for all users ensures safe and efficient operation.

Safety precautions are essential when using air tools. Always wear appropriate personal protective equipment. This includes safety glasses, gloves, and hearing protection when necessary. Ensure proper ventilation in the work area. Never use compressed air to clean clothing or skin. Disconnect tools from the air supply when not in use. Secure loose clothing and tie back long hair to prevent entanglement. Follow proper procedures for changing accessories or making adjustments. Be aware of the tool’s potential for kickback during operation. Keep work areas clean and free of trip hazards. Regularly inspect air hoses for signs of wear or damage.