Here’s the blog post as requested:

Understanding installation boxes

Installation boxes are crucial components in electrical systems. They provide a safe enclosure for wire connections and electrical devices. These boxes come in various sizes, shapes, and materials. Typically, installation boxes are made of plastic or metal. They protect against moisture, dust, and physical damage. The choice of box depends on the specific application and local electrical codes.

There are three main types of installation boxes: flush-mounted, surface-mounted, and floor boxes. Each type serves a unique purpose in electrical installations. Flush-mounted boxes are installed within walls or ceilings. Surface-mounted boxes are attached to the exterior of walls. Floor boxes are designed for installation in flooring systems.

When selecting installation boxes, consider factors such as box volume, material, and environmental conditions. The box volume must accommodate the number and size of conductors. Metal boxes offer better heat dissipation and grounding capabilities. Plastic boxes are lightweight and corrosion-resistant. Environmental factors like moisture and temperature affect box selection.

Flush-mounted boxes: A seamless solution

Flush-mounted boxes are popular in residential and commercial buildings. They provide a clean, streamlined appearance by sitting flush with the wall surface. These boxes are installed during construction or renovation. They require cutting into drywall or other wall materials. Flush-mounted boxes come in various depths to accommodate different wall thicknesses.

Common applications for flush-mounted boxes include outlet receptacles, light switches, and junction boxes. They are available in single-gang, double-gang, and larger sizes. Single-gang boxes typically measure 2″ x 3″ x 2.5″ deep. Double-gang boxes are 4″ x 4″ x 2.5″ deep. Larger boxes are used for multiple devices or complex wiring configurations.

When installing flush-mounted boxes, proper support is crucial. Boxes should be securely fastened to wall studs or joists. Use appropriate mounting brackets or supports for stability. Ensure the box is level and at the correct depth for a proper finish. Leave enough slack in the wires for easy connections and future maintenance.

Surface-mounted boxes: Versatile and accessible

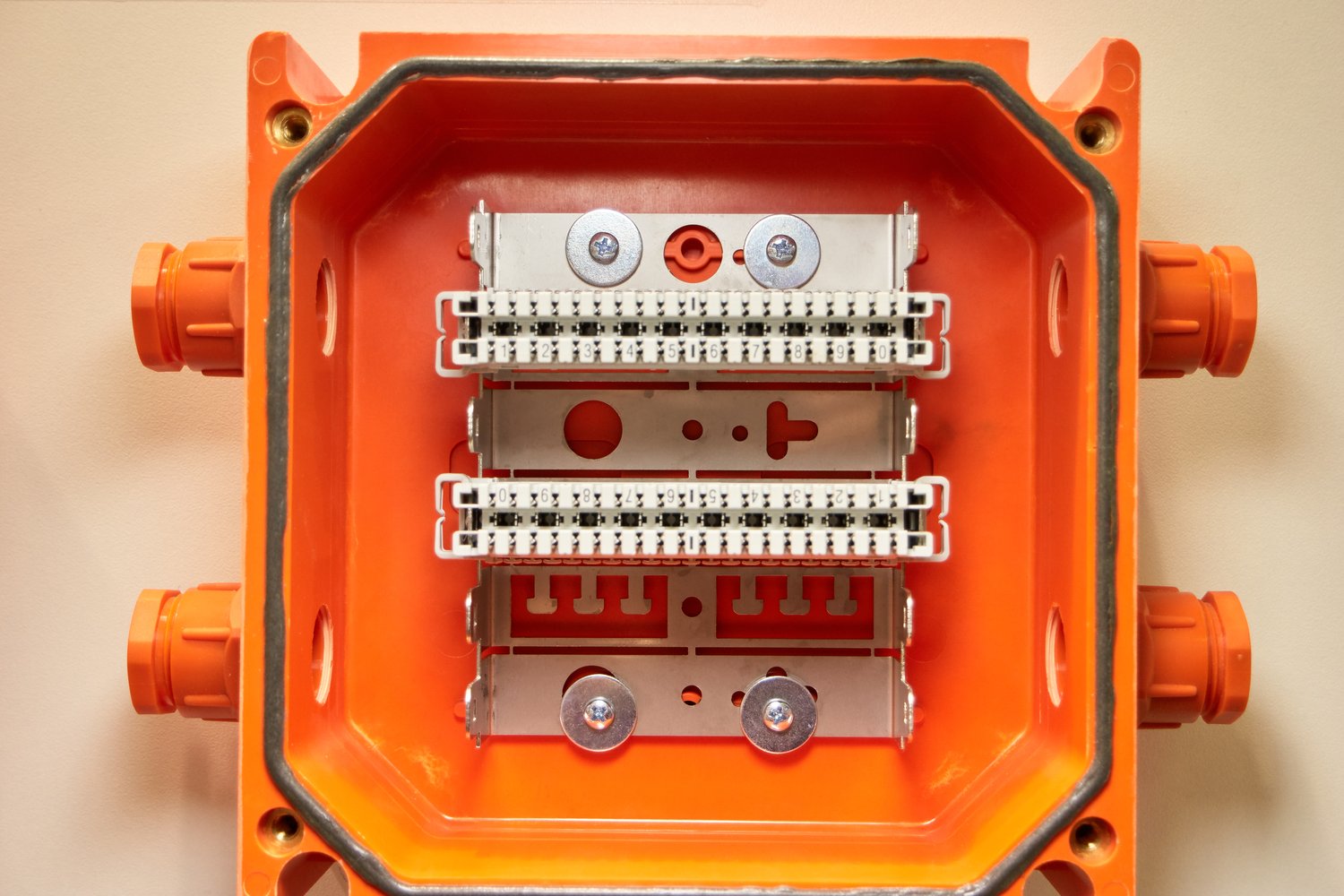

Surface-mounted boxes offer flexibility in electrical installations. They are ideal for retrofitting or adding electrical devices to existing structures. These boxes are mounted directly on walls, ceilings, or other surfaces. They eliminate the need for cutting into walls, making installation quicker and easier.

Surface-mounted boxes are commonly used in industrial settings, workshops, and garages. They provide easy access for maintenance and modifications. These boxes are available in various sizes and configurations. Standard sizes include 4″ x 4″ x 2.5″ and 4″ x 4″ x 1.5″. Larger boxes accommodate multiple devices or complex wiring.

When installing surface-mounted boxes, choose appropriate mounting hardware. Use screws, anchors, or adhesives suitable for the mounting surface. Ensure proper sealing to protect against moisture and dust ingress. Consider using weatherproof boxes for outdoor applications. Follow local electrical codes for proper grounding and wire management.

Floor boxes: Convenient power access

Floor boxes provide power and data connections in open spaces. They are installed in concrete or raised floors. These boxes offer a convenient way to access electrical outlets without wall-mounted devices. Floor boxes are commonly used in offices, conference rooms, and auditoriums.

There are two main types of floor boxes: poke-through and in-floor. Poke-through boxes are installed after the concrete is poured. They require core drilling through the floor. In-floor boxes are set before concrete pouring. They come in various sizes, ranging from 2.5″ to 10″ in diameter. Larger boxes accommodate more connections and devices.

When selecting floor boxes, consider load capacity and protection rating. Choose boxes rated for the expected foot traffic and equipment weight. Look for boxes with an appropriate IP (Ingress Protection) rating. This ensures protection against dust and water ingress. Follow manufacturer guidelines for proper installation and sealing of floor boxes.

Choosing the right installation box

Selecting the appropriate installation box is crucial for a safe and compliant electrical system. Consider the following factors:

- Application: Determine whether flush-mounted, surface-mounted, or floor boxes are suitable.

- Box volume: Calculate the required volume based on the number and size of conductors.

- Material: Choose between plastic and metal boxes based on environmental conditions and grounding requirements.

- Local codes: Ensure compliance with electrical codes and regulations in your area.

Proper installation is as important as selecting the right box. Follow these best practices:

- Use appropriate mounting hardware and techniques.

- Ensure proper support and stability for the box.

- Maintain correct box depth and alignment for a professional finish.

- Allow sufficient wire length for connections and future maintenance.

- Seal boxes properly to protect against environmental factors.

By carefully considering these factors and following proper installation techniques, you can ensure a safe and efficient electrical system. Always consult with a qualified electrician for complex installations or when in doubt. Proper selection and installation of boxes contribute to the longevity and reliability of your electrical infrastructure.